THE KETTLE FOR A MAN

Short Video |

Longer Video |

THIS IS THE LOUDEST KETTLE EVER

Now i,ve seen a lot of pulse jets on the internet some big some small but they are very often not used for much. Some people put them on RC planes and some have made go carts but they don't go super fast and the videos are usually complete shit so i decided to take a different approach to these fantastic devices. The pulse jet im using in the kettle is a valveless pulse jet so has no moving parts, its essentially a special shape pipe. The plans for this are available on a website called beck technologies but ive scaled them down to a size that fitted the kettle. It seems the smaller they are the harder they are to start as i'm guessing the window to get correct air gas ratio is abit smaller but could also be my maths being slightly of when scaling down. To start these things people use an air line to blow air into them to sort of prime them and get air ratio right etc but with this one being small i found having a fixed tube for the air much easier as holding your hand still enough is just a pain. The next problem you have is when surrounded by water you are effectively water cooling the jet and a jet this size does not like this. While making the jet on its own it would not stay running without the air still being forced in it from the air line until it was glowing red hot and as it got hotter you had to turn gas down as it would over gas n kill it so to keep the JETTLE running you need a controllable forced air flow........Que. build pics

THE TRICKY BITS

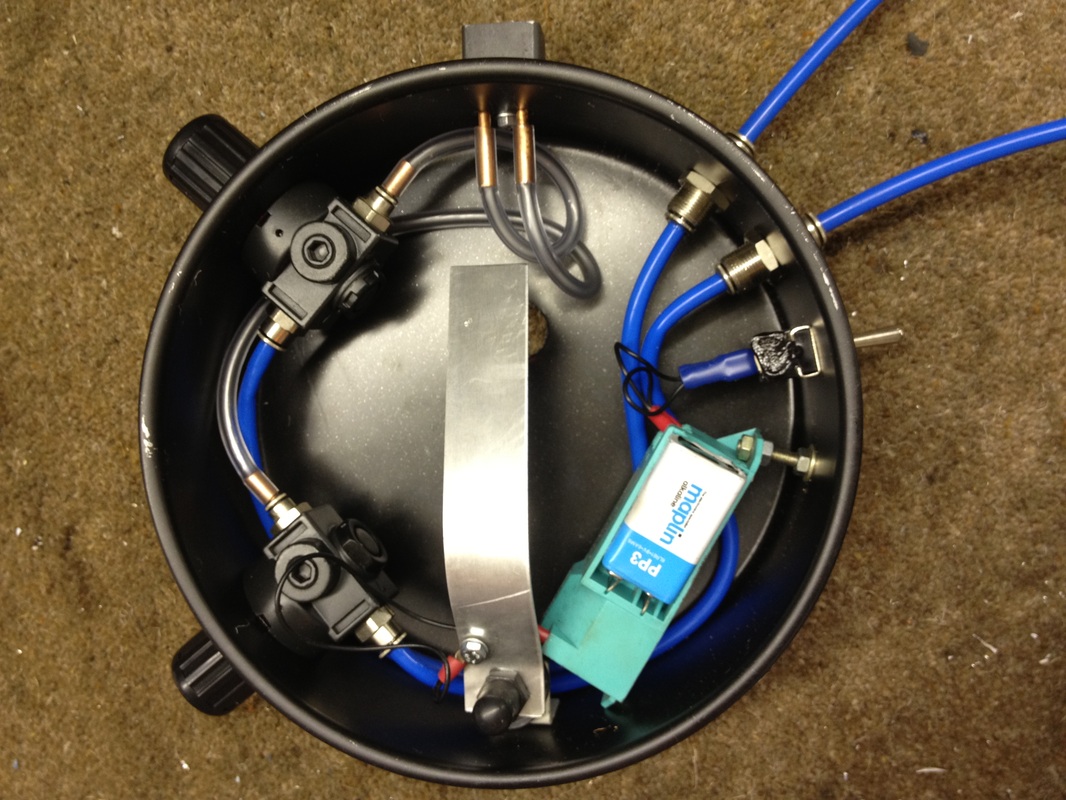

Now of corse if you build your own you may have a better method but here is how i did it. To start with get a stove kettle then you have no electric elements inside to remove or work round, cut the handle to allow the exhaust of the jet through and in the bottom drill hole the same diameter as your spark plug thread as you use the spark plug to hold the jet in place this has to be water tight so kettle does not leak or jet fill with water. Find a cake tin with similar diameter to kettle base and drill hole trough where spark plug needs to stick through. Now this cake tin is going to be you control hub so make it neat or you'll have a wobbly shit jettle. To generate the spark i use these 9v piezo units you get in gas fires but they are around £30 + but as i'm a gas fitter ive collected them over the years but anything that will make a frequent spark will do. Fit in to the tin so when the spark plug comes through the hole it connects with the sparker, i did this with a flexible piece of ali (make sure spark doesn't spark anywhere else but the plug so using plastic bolts etc for this bit is a must). Next part is your gas n air supply i used 6mm air fitting of the inlet then reduced to 4mm after control valve. The control valves are just regulators from air compressors and are around £6 on eBay as you can get cheap ones. To divert the gas/air up to the inlets i made a small manifold and this is just a square of steel with holes drilled in that meet up and pipe pushed in the holes, there was no sealant used as pressures are very low and a small leak is not going to end in a mushroom cloud just might make you jump haha. The pipes going up into jet where very small copper tubes which i can only think are for model makers but i can think of another alternative as they have to take the heat so plastic no good. Thats about it as all info about making the pulse jet is better explained on other websites, this one is made from mild steel but stainless is best used as tea will taste better lol.