The slighty posher homemade jet engine

The pulse jet is the thug of the jet family and the turbojet the middle class nutter.

Ok so i,ve done pulse jets and it seemed only right to make one of these as they are little more sophisticated in appearance and have a more refined jet engine sound. However they are still quite simple in the fabrication is just a couple of tubes with some holes drilled in and that really is all they are. The extra work comes in the fact the engine is 2 separate pieces ,the flame tube and the housing. making these fit together nicely takes a little more time than just rolling sheet metal pulse-jet style. So below ive laid out all the pieces and in my next video will go through the maths to work out what size they should all be.

Adding it all up

So on to the maths and it is really quite simple just measure the diameter of the intake on the turbo times it by 2 and that is the diameter of your flame tube. For the length of the flame tube times it by 6. On to the housing which the flame tube sits in, you need roughly a 15mm gap all around your flame tube requardless of its size unless its fuchin massive so just add 30mm to your flame tube diameter and thats your housing diameter. The length of housing is same as flame tube and the housing end is extra and should be short as possible with smooth entry to turbo. Now on to the holes in the flame tube which is where i get a little liberal with how to do this, You want the holes to get bigger as they go along so you get a nice even burn the first set of holes are for the primary air so its best to have lots of smaller ones to promote a more even mix then the other sets can be a bit more spread out. You may be able to play around with this for more power or easy start up extra but thats up to you. To calculate these holes you need the area of the turbo intake and the first set must add up to 30% of this with the second set 20% and third set 50% so work at your intake area by doing pie r squared which is 3.142 times the radius squared (squared is number times itself like 4 times 4) then divide this number by 100 and times result by whatever % your after which will give you the area of all your holes in that section so you now need to decide how many holes you want then divide that number by the same amount which will give you the area per hole then do the pie r squared bit again on what you think they might be and trial and error will give you your drill bit size. no get to it.

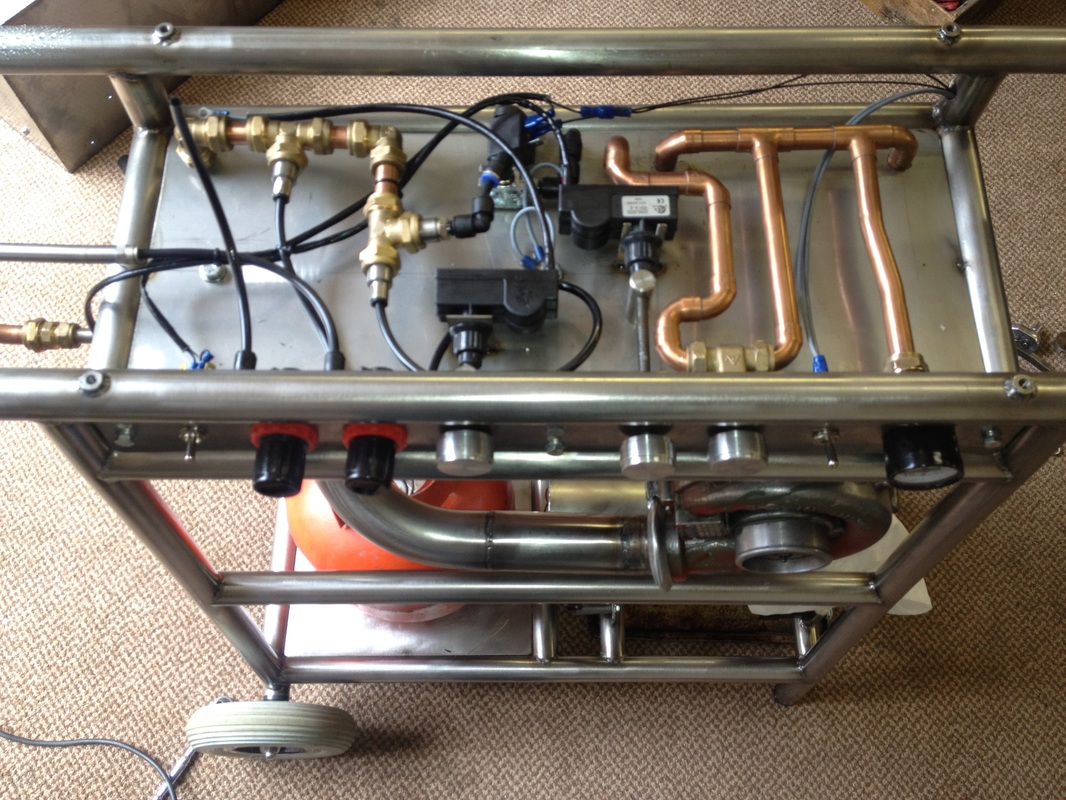

THEN THERES ALL THE OIL N SPARK BITS

I,ve not written this bit yet so heres a random picture

Oil is good for your turbo.......

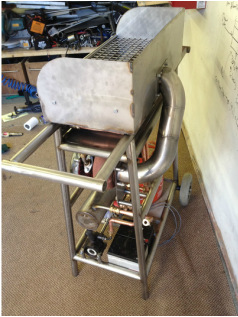

SO I PUT IT IN A BBQ OF CORSE

I thought i,d do something diffrent

So i can here people saying "why not put it in a Go cart or bike" but thats been done so many times before so why repeat others work. No i,m Colin Furze and i do my own thing and after making THE JETTLE to make tea it seemed fitting to make my dinner using a jet engine to. The frame made all of stainless steel and everything else copper or brass so there are no parts that will go rusty which is perfect for a British BBQ hehe. This also was quite a good house for the turbojet as all the components like the oil pump the oil resovour and various other bits fitted very neatly into the frame and i don't mind saying i made a bloody good job of it. Can you cook on it ,well sort of but you'll end up with raw meat on inside which is why i added the "normal" front grill so its not completely useless but its all about the noise at the end of the day which is bloody amazing. next video will go through the controls etc with more detail.